Brushless Blower Motor

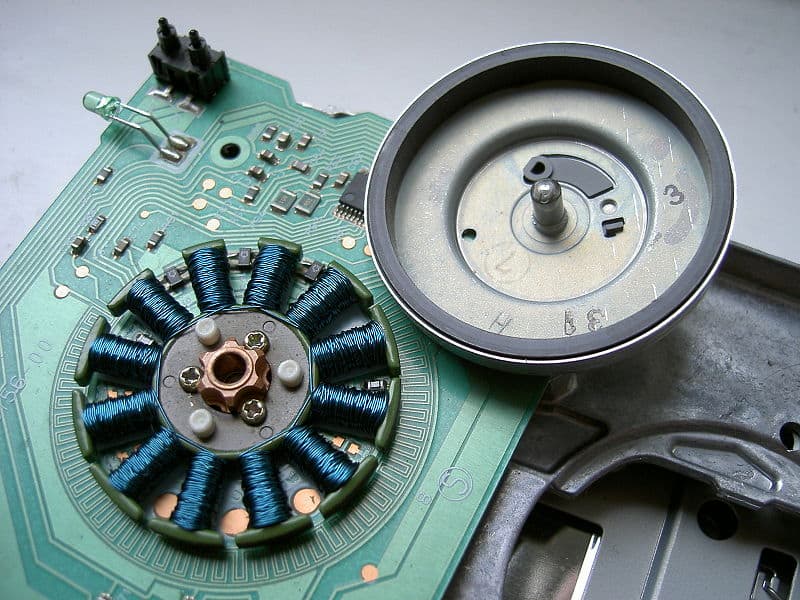

(illustration: Wiki commons) This disc drive motor has magnets in the hub that rotates around the windings. A control unit turns on voltage to each winding at the right time.

by Jacques Gordon

A growing number of cars use a brushless blower motor in the ventilation system. A brushless motor has fewer parts that wear, won’t make sparks as it runs, and its speed can be adjusted infinitely rather than just low-medium-high. A brushless-motor blower can be operated at extremely low speed to keep air moving through the cabin with minimal effect on cabin temperature. There’s also no blower motor resistor that requires cooling.

An electric motor consists of two sets of magnets, one inside the other, and it works by aligning magnetic fields of like polarity so they repel each other. By holding one magnetic field stationary and allowing the other to rotate, constantly switching electromagnetic fields off and on to keep north/north and south/south poles aligned creates rotating magnetic repulsion forces that make the motor rotate.

In a typical brush-type DC blower motor, permanent magnets are fixed to the housing. Wire windings are mounted on the rotating shaft, and each end of each wire is soldered to electrical contacts on opposite sides of the shaft called commutator bars. The brushes touch the commutator bars, completing an electrical circuit. When voltage is supplied to one of the brushes, current flows through the wire winding and out through the other brush to ground, creating a magnetic field in that one winding. Voltage level determines the strength of the magnetic fields and therefore motor speed. Since the brushes actually touch the commutator bars, they behave like mechanical switches as rotation of the shaft brings each commutator bar into and out of contact with each brush.

In a brushless motor configured as above, the windings are held stationary while the permanent magnets rotate, and voltage to each winding is pulsed on and off electronically with a control unit. Pulse width modulation (voltage-on time) determines blower speed. But without mechanical brushes to align with specific windings, the control unit needs to sense the position of the rotating magnet so it can switch on the current to each winding at the right time. Some brushless motors, particularly large ones used in hybrid-vehicle motors, use Hall-effect sensors to report rotor position to the control unit. But smaller motors use a simpler and less expensive solution.

When a magnet moves past a coil of wire, electric voltage is generated in the wire. By sensing the rise and fall of voltage in one of the windings that’s turned off, the control unit can sense the position of the magnet.

The Mobile Air Conditioning Society’s blog has been honored as the best business to business blog in the Automotive Aftermarket by the Automotive Communications Awards and the Car Care Council Women’s Board!

When having your mobile A/C system professionally serviced, insist on proper repair procedures and quality replacement parts. Insist on recovery and recycling so that refrigerant can be reused and not released into the atmosphere.

If you’re a service professional and not a MACS member yet, you should be, http://bit.ly/10zvMYg for more information.

You can E-mail us at macsworldwide@macsw.org . To locate a Mobile Air Conditioning Society member repair shop in your area.

The 35th annual Mobile Air Conditioning Society (MACS) Worldwide Training Conference and Trade Show, Meet me at MACS! will take place February 5-7, 2015 at the Caribe Royale Hotel and Convention Center.

Leave a Reply